Running and owning your business can be rewarding but also requires hard work and commitment. Getting down to every last detail is paramount to the success and survival of your business. Finding quality commercial furniture is just one of the many puzzle pieces businesses need to put together. It might be more convenient and affordable for you to pick up a few chairs and tables from your local retail store but doing so might cost you in the long run.

Residential vs Commercial Furniture

Differences between residential and commercial furniture

Wood Type

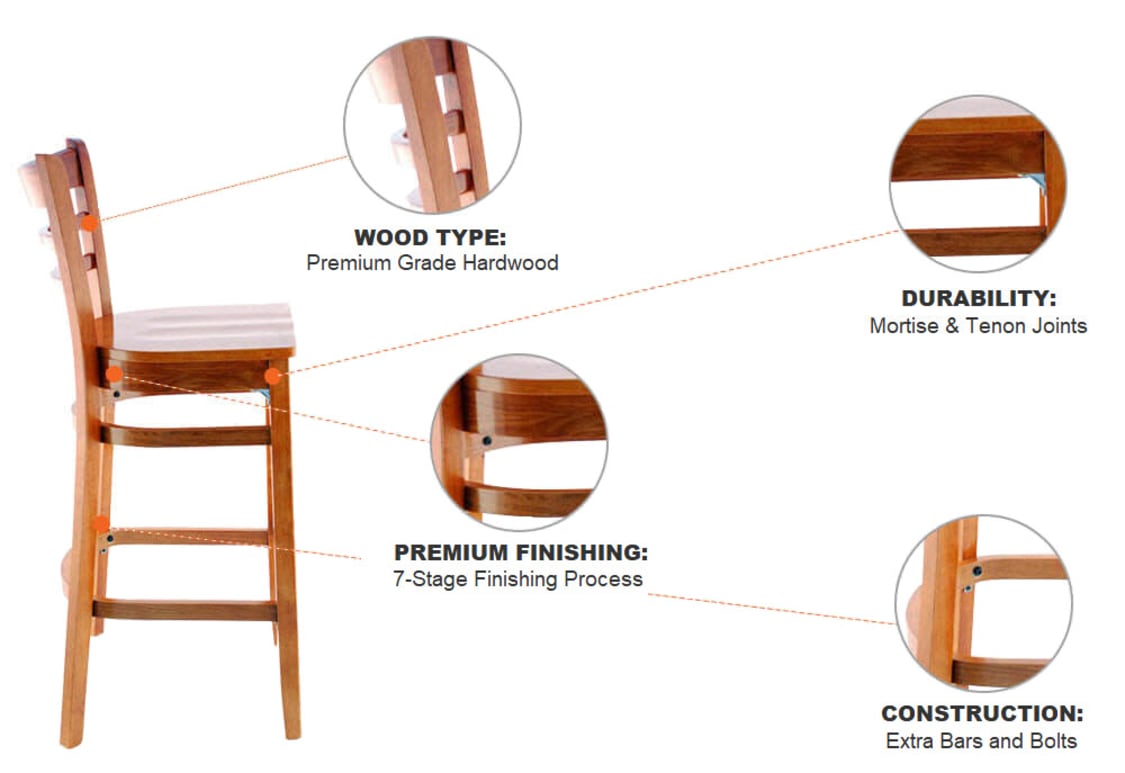

In most parts of the United States for practically all interior woodwork, such as flooring, trim, furniture, etc. a moisture content below 12 percent is recommended. In contract furniture we use hard wood with 6-7% moisture content which adds to the wood's toughness and durability.

Durability

The metal frame is powder coated and baked making it more resistant to rust and flaking. Powder Coating also results in a thick, dense finish with a smoother surface which attracts less dust and allows less dirt to accumulate making it both easier to maintain and more hygienic.

For upholstered furniture the seat is first covered in foam padding which comes in a variety of densities, firmness and fire resistance. Unlike residential furniture contract furniture comes with more stringent safety codes and often, for an additional small fee the most stringent codes such as CAL 133 can be applied.

All foams include both density and firmness measurements and usually the firmer a foam is the higher it's density and weight. While firmer foam is more expensive it is also more comfortable and lasts longer. A density of 2.0-2.5 is the appropriate range for upholstered chairs and booths used in restaurants and other busy venues while the most commonly used foam density for residential furniture sold in the U.S. is 1.8.

Warranty

Strength

Metal residential furniture is typically made using 22 or 24 gauge steel frame compared to 16-18 gauge steel in commercial grade furniture (the lower the gauge number, stronger the metal frame).

Testing and Accreditation

- Back Rest Strength Test

- Drop Test

- Stability Test

- Leg Strength Test

While initially more expensive, a core benefit contract furniture has over residential furniture is its ability to outlast competition. Running your business is costly and the lower your expenses are the better. Having to constantly replace and rebuy furniture and other items for your business is going to burn a hole in your wallet and consume your valuable time. Guaranteed to stand the test of time, the resilience of commercial restaurant furniture reduces the need to make numerous purchases and replacements. In such instances where you need to replace a restaurant chair or a base for a restaurant table, you can purchase replacement or additional pieces when buying specially formulated commercial furniture.

The table below sums up the differences between residential and commercial furniture:

| Commercial Furniture | Residential Furniture | |

| Wood Type | Hard Wood - maple, oak, beechwood; 6-8% moisture content | Soft Wood - rubberwood, pine; up to 12% moisture content |

| Durabilty | P.U wood finishing (7 stages process with scratch resistant top coat ); powder coated metal; 2-2.5 dense foam padding | Residential grade wood finishing; plated metal; 1.8 dense foam padding |

| Warranty | 3 years - lifetime structural warranty | 1 – 12 months |

| Strength | weight capacity of 350 pounds or higher; 16-18 gauge steel frame | weight capacity of 250 pounds; 20-22 gauge steel frame (lower gauge is stronger) |